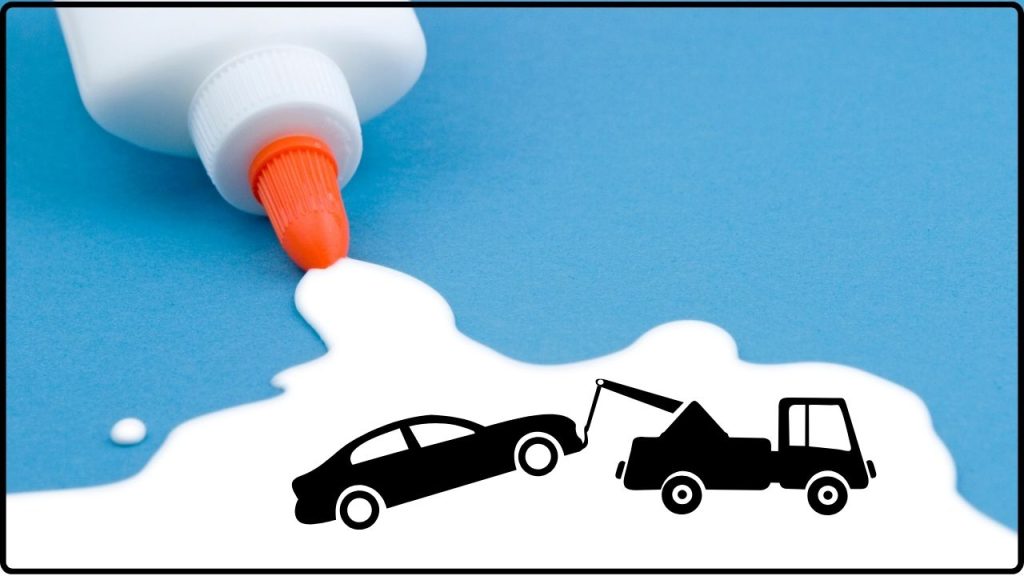

This New Glue Is So Strong It Can Tow a Car: Innovation often comes from the most unexpected places. In this case, the next big leap in engineering didn’t come from high-tech materials or space-age alloys — it came from your kitchen fryer. Yep, that greasy, brown leftover oil you usually toss after making chicken wings might be the secret behind a new kind of glue so strong it can tow a car. And scientists believe this could be a legit alternative to traditional welding in many applications. Let that sink in. This isn’t just about glue — it’s about rethinking how we build our world, with an eye toward sustainability, cost-efficiency, and safer working conditions.

Table of Contents

This New Glue Is So Strong It Can Tow a Car

From fried chicken grease to gluing together the future — this glue is proof that innovation doesn’t always come in high-gloss packaging. Sometimes it’s born from what we throw away. By turning waste into strength, this eco-friendly glue not only challenges how we bond materials, but also how we approach sustainability, manufacturing, and design. For industries that need to move fast, stay green, and keep costs down, this might be the stickiest — and smartest — idea yet. Stay tuned. The age of welding may have just met its match in a bottle of recycled oil.

| Topic | Details |

|---|---|

| Breakthrough | High-strength adhesive made from used cooking oil |

| Strength | Holds over 270 pounds, tows a car uphill |

| Eco-Friendliness | Fully recyclable; derived from kitchen waste |

| Potential Industries | Automotive, aerospace, construction, marine |

| Developed By | University of Surrey and University of Bristol (UK) |

| Technology | Polyester polymer-based adhesive chemistry |

| Official Resource | Popular Mechanics Article |

What Makes This New Glue So Special?

The adhesive was created by a team of chemical engineers and material scientists at the University of Surrey and the University of Bristol in the UK. Their mission? Build a super-strong, recyclable glue from something that would otherwise end up in the trash.

Using waste cooking oil, the scientists created polyester-based polymers that form strong, flexible chains. When applied between surfaces — like two pieces of stainless steel — the material cures and forms a bond so tough it can hold more than 123 kilograms (≈270 pounds) and even tow a sedan uphill.

The breakthrough shows that the bond is not only strong in static lab conditions, but durable under real-world mechanical stress — something that separates it from conventional adhesives.

And the best part? This glue is fully recyclable. It can be chemically broken down and reconstituted for reuse, making it a valuable asset in the circular economy.

The Science Made Simple

Let’s not get too bogged down in chemistry class, but here’s a simplified breakdown:

- Used cooking oil contains fatty acids, which are hydrocarbon chains.

- These are chemically modified to become polyesters — flexible, water-resistant polymers.

- The polymers form cross-links between surfaces, similar to how Velcro or a zipper locks together.

- Once cured, this glue doesn’t just stick — it integrates at the molecular level, making it highly resistant to pulling, shearing, and heat.

Unlike super glue, which can become brittle, or welding, which requires dangerous heat and energy, this new adhesive remains strong and adaptable in a wide range of conditions.

“This innovation proves that you don’t always need heat, electricity, or brute force to create lasting bonds,” says Dr. Andrew White, a materials science lecturer not involved in the project.

Why This New Glue Is So Strong It Can Tow a Car Could Change How We Build?

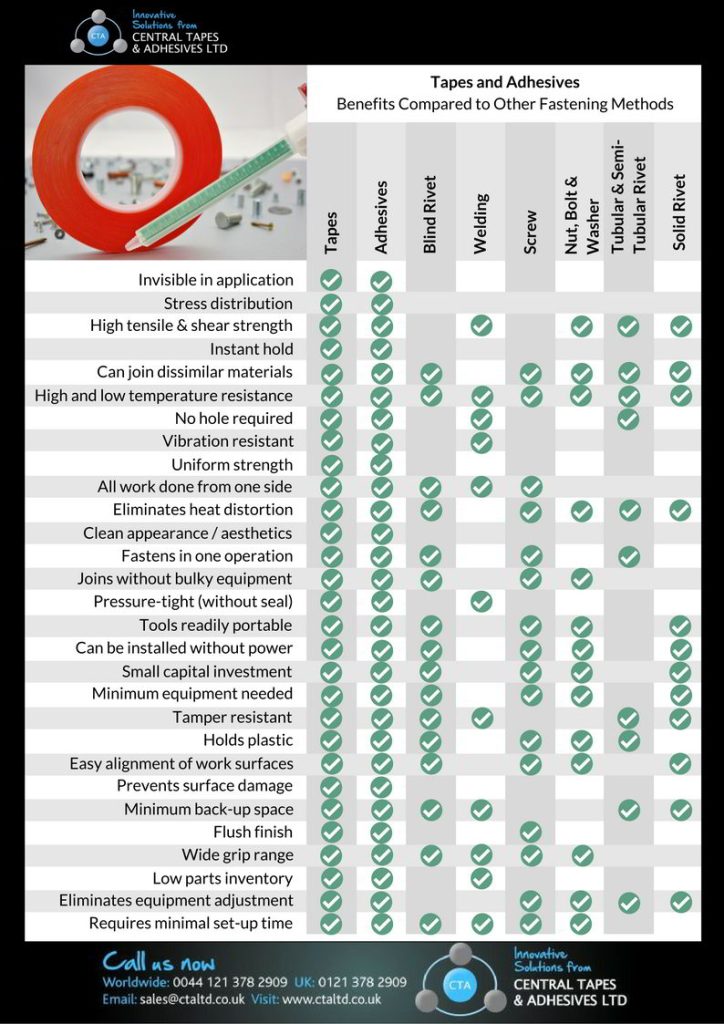

Currently, welding is the go-to method for bonding metals in industries like construction, shipbuilding, automotive manufacturing, and aerospace. But welding comes with serious drawbacks:

- It requires extremely high heat (often over 2,500°F)

- It produces hazardous fumes

- It can weaken metal parts through warping or thermal stress

- It often requires specialized equipment and training

Now compare that to this new glue:

- No heat required

- No toxic fumes

- No expensive equipment

- Applicable to various materials (metal, glass, plastic)

This could seriously disrupt how components are assembled — especially in modular construction, electric vehicle assembly, and lightweight aircraft design.

Hypothetical Use Case: Tesla or Boeing Adopts This Glue

Imagine Tesla wants to streamline its EV door panel assembly. Instead of welding or screwing multiple parts together — a process that adds weight, complexity, and labor — it could use this glue to bond metal, plastic, and fabric layers in one fast step.

Boeing, too, could use it for interior panels and lightweight insulation boards. The glue’s strength-to-weight ratio would help aircraft meet strict weight limits while boosting durability and acoustic dampening.

The Environmental Bonus: Turning Waste Into Wealth

The U.S. alone generates over 3 billion gallons of used cooking oil annually. Most of it is thrown out or used for low-grade biodiesel. This innovation offers a new purpose for that waste — a high-value, high-performance material.

According to the EPA, converting waste streams into industrial products is one of the best ways to support green manufacturing. The glue ticks several boxes:

- Reduces reliance on fossil-fuel-based adhesives

- Turns trash into a product with economic value

- Reduces energy consumption in manufacturing

- Prevents used oil from polluting waterways

For companies aiming to meet ESG (Environmental, Social, and Governance) goals or net-zero carbon targets, this glue could be a valuable ally.

Will It Really Replace Welding?

Let’s be real — not entirely.

Welding is still essential for high-stress, high-temperature applications — think bridges, pipelines, skyscraper beams, or jet engines.

But in cases where:

- Heat would damage sensitive components

- Weight is a concern

- Different materials need to be bonded

- Safety or speed matters

This glue might not just be an alternative — it could be superior.

Expert Opinions & Industrial Feedback

While still in the testing stage, the adhesive has already caught attention.

“This glue could change how we design everything from household appliances to satellites,” said Jane Thompson, an R&D consultant at General Electric. “We’re always looking for safer, greener options. This one checks all the boxes.”

“Adhesive bonding has been overlooked in industrial settings due to durability concerns. But if this holds up under repeated testing, it could change how engineers think about structural joins,” noted Dr. Peter Langston, welding technology expert.

Pros and Cons Recap

| Pros | Cons |

|---|---|

| Recycled from waste | Still under research |

| Strong enough to tow vehicles | Long-term durability under real-world conditions unproven |

| Bonds dissimilar materials | May not handle extreme heat or pressure |

| Scalable for industry | Not yet commercially available |

Practical Advice for Industry Pros

If you’re in engineering, manufacturing, or supply chain leadership, here’s what you should be doing right now:

- Watch the space – This glue is still being optimized. Start following updates from the University of Surrey’s materials department.

- Evaluate current bonding methods – Can adhesives replace welding in your process? Identify low-stress joints.

- Partner with research labs – Early adoption can give your business a competitive edge.

- Train your workforce – Educate teams on hybrid bonding systems that use both adhesives and traditional fasteners.

Earthquake Science Just Changed Forever; Researchers Unveil a Groundbreaking Math-Based Method

Science Confirms It: There’s a Neurological Reason December Feels Like It Comes Faster Every Year

Chair-Pulling Body Language – What Yale Psychologists Say This Habit Reveals About Personality